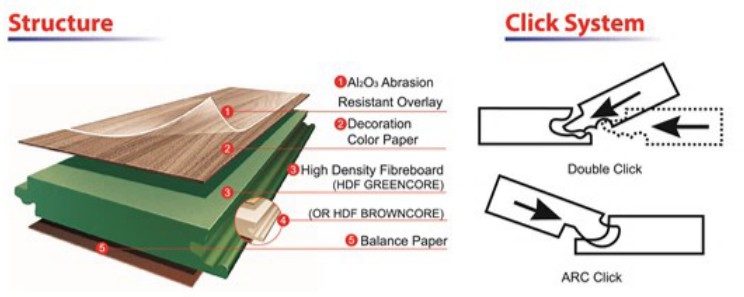

What is laminate flooring made of?

The top layer – The AC Overlay

The very first layer that you can see is the overlay. It’s clear, so it mightn’t be obvious on first glance, but it’s always there. It is this clear overlay that determines the AC level of the floor.

AC stands for Abrasion Criteria and gives you a really good idea of what you can expect in terms of wear and tear from the floor you choose. Essentially, the higher the AC, the more resistant the floor will be to wear and tear.

The next layer – Decorative Paper

Once you get down to the next layer, this is where most consumers get excited. But in fact, this layer is only a piece of paper! This layer that makes a laminate floor look great.

The bit in the middle – High Density Wood Fibre

The core board of any laminate floor is really important and the range we stock at Wood and Beyond has High Density Wood Fibre at its core. What this means is that you get a really sold under foot feel as well as a stable surface for your floor.

When you choose a low quality laminate floor, the core board can often be made of cardboard, which means that every imperfection in your subfloor eventually becomes a real problem, and you end up with an uneven and unattractive floor very quickly.

The bottom bit – the backing layer

After the core board, there’s a backing layer that serves to protect the core board and acts as light insulation. Once again, the backing layer is an important part of the overall board make up as it means your core board isn’t exposed directly to your sub floor leaving it at risk of damage.

Once all these layers are bonded together, the joints are then sealed with a paraffin covering that protects the floor against humidity.